Vaccination center design

The SmartUnit makes it quick and easy to set up immunization centers and other temporary healthcare facilities. In doing so, the system can show its high flexibility.

Vaccination centers designed quickly and flexibly

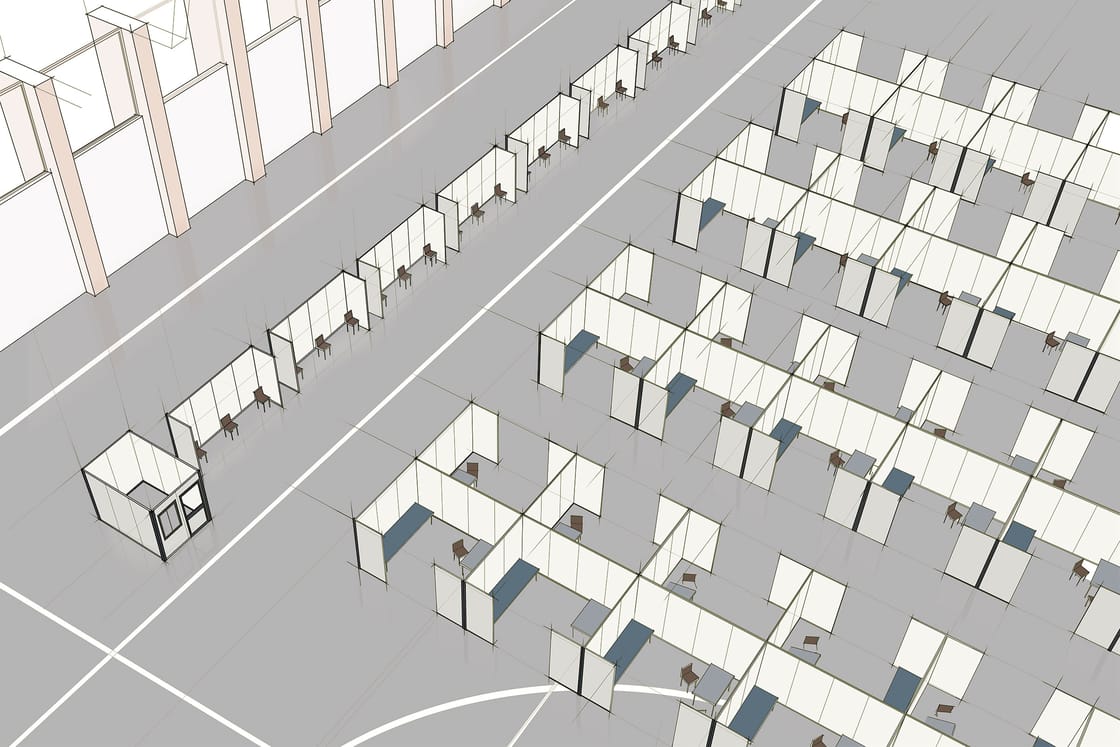

Even before the first vaccines against COVID19 diseases were approved, planning and construction of numerous facilities in which the vaccine will be administered to the population in the future began in Germany and other countries. At least one of these new vaccination centers will be established in each county and city in this country and will be put into operation as soon as possible. In city halls, sports facilities, former warehouses and factories, i.e. wherever larger covered spaces are available, after the start-up of voluntary mass vaccination, thousands of people will be led daily through “vaccination streets” and then advised and “treated” by trained personnel – all, of course, while maintaining the necessary distances and intimacy. There should also be a rest area with a lounger per person.

Delivering the vaccine doses, syringes, masks, gloves and documents on time, as well as supplying the staff – all this is logistically extremely demanding. And the structural design of the halls and rooms also requires unprecedented effort. The best way to set up centers with dozens of separate rooms that can be used as consultation sites, vaccination booths and rest rooms is likely to be with flexible partitions that can be easily installed and securely joined together.

SmartUnits from WSM in use

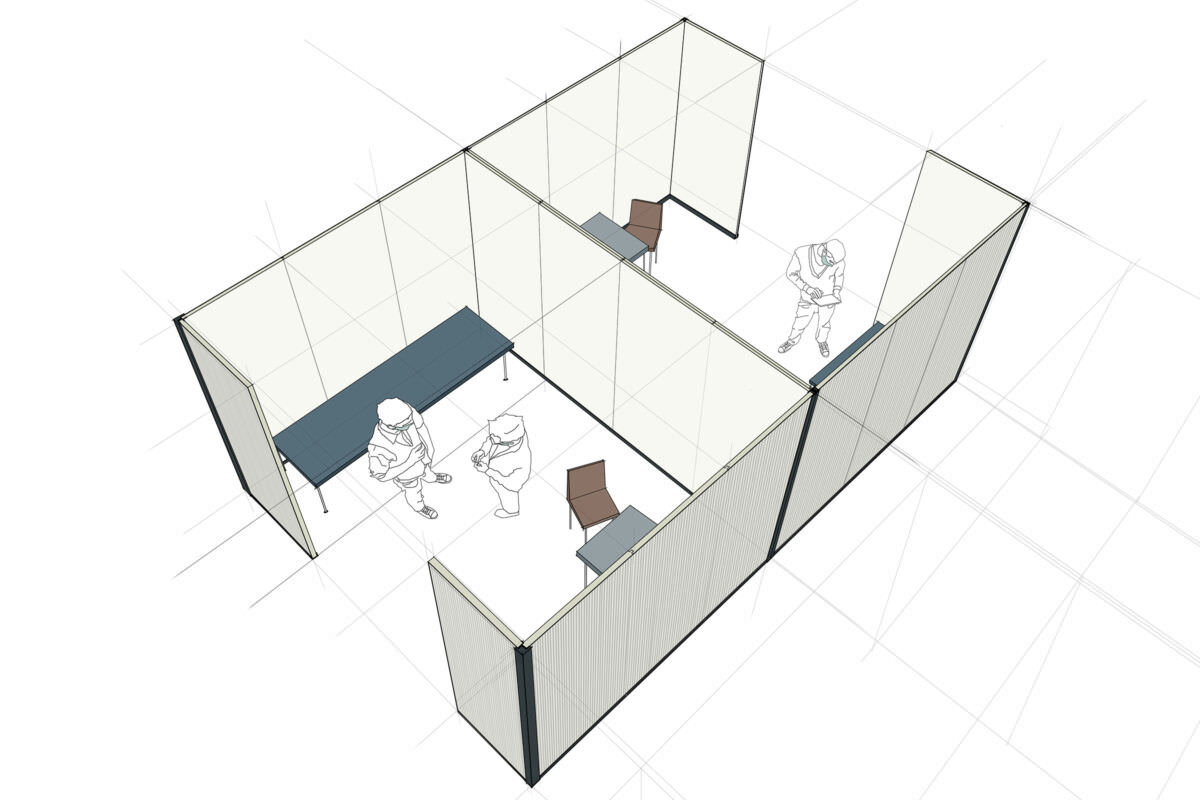

WSM’s SmartUnit mobile modular room systems are perfect for this. The system consists of different sandwich elements, which are both light and very stable due to their advanced construction. An intelligent tongue-and-groove plug-in system enables individual room solutions that are ready for occupancy in the shortest possible time. The stability of the system also allows the installation of uncovered spaces and does not require its own floor, which allows barrier-free access.

Simply plugged together by hand, it allows dozens of vaccination booths to be quickly and easily assembled, disassembled and just as easily reassembled elsewhere – even in hard-to-reach places thanks to the modular concept. The high-quality sandwich panels made of aluminum are bright, easy to clean and easy to wash; thus, high hygienic requirements can be met. Building material class B1 ensures adequate fire protection.

Accessories also make the difference

In addition to solid wall panels, there are also those with fixed glazing, tilt/turn and sliding windows, elements with floor-to-ceiling fixed glazing and doors in DIN format, optionally also made of glass. Closed sanitary rooms or rooms for storing sensitive products can be realized in no time with matching roof elements and corner posts. A basic electrical installation package including electric wall heating is also available, as well as wall-mounted ventilators and floor-standing air conditioners.

The barrier-free nature of the rooms created with a SmartUnit is also practical: since they do not require their own floor, access or entry is possible at ground level, i.e. without edges and thresholds to overcome at any time.

A manufacturer that thinks along

As one of the first suppliers of modular room systems, WSM knows what is important when providing flexible partitions and rooms at short notice. WSM guarantees a short delivery time, with shipping in convenient stacking boxes.

The SmartUnits can be easily assembled on site by auxiliary personnel.